Over the last few years, LED lights have become one of the most commonly used decorative options out there when it comes to decorating indoor areas. In addition to being aesthetically pleasing, LED lights are also extremely versatile and can be used for multiple purposes.

In addition to these advantages, newer technology have made it possible for LED lights to be manufactured for very cheap, easily making them one of the most affordable options.

Whether you want to install lighting on the wall or behind furniture or appliances, LED light strips are an option you just can’t go wrong with.

However, as with walls, furniture and appliances, often you’ll need your LED strips to make a 90 degree turn. You may think you can just bend the strips without a problem, but you’d be wrong.

LED strips are made of very small and delicate components. This means that bending or putting tension or stress on the strip itself may damage these components, possibly causing the entire strip to malfunction.

Well the good news is its not entirely impossible. With the help of a few additional tools, LED strip 90 degree corners can be achieved without damaging the strip.

How To Make A LED Strip 90 Degree Corner

Using just a few useful tools, you’ll be able to make your LED strips bend 90 degrees without any problems.

There are a few options you can consider when it comes to alternatives. The most commonly used options out there include back to back light strip connectors, gapless pin connectors, jumper cord connectors, etc.

90 Degree Corner Connectors for LED Strip Lights

Now that we’ve established that its possible to use LED strip 90 degree corners, lets look at the different options that are out there in detail.

Back to Back LED Strip Light Connector

The most commonly used LED strip light connectors for 90 degree angles are back to back connectors. Essentially, the two ends of the connectors are connected through a 90 degree L strip.

The advantage of this connector is that visually, it looks as if you have a continuous strip that turned 90 degrees without any bending or twisting. If you’re particular about details, this connector looks very organized and orderly.

JACKYLED – 4-Pin LED Connectors 10-Pack

L-shape connectors make joining numerous sections at a 90-degree angle a breeze.

Gapless Pin Connectors

Gapless pin connectors are basically the same as back to back connectors, however instead of the two ends of the connectors being connected with a 90 degree strip, the ends are one single component that basically turn 90 degrees in the middle.

So its basically a regular LED strip connector that has a 90 degree angle.

The biggest advantage of these connectors is that as the two ends are placed very closely together, the connected strips look continuous with very little gap between them.

Jumper Cord Connectors

Just like the other two connectors, jumper cord connectors also use the same principle. The difference is that the two end of the connectors are connected through wires which are covered using insulated chords.

This connector is particularly useful if you want to have a little wiggling room on your 90 degree turn. Although these cords do not make the strips look continuous, the long wires allow you a lot more independence in terms of where you want to place your 90 degree turn.

JACKYLED – 5″ 4 Pin LED Light Strip Connectors

Strip-to-strip jumper extension connectors that are 3/8″ (10mm) wide and solderless. Can be used with RGB 4-pin strip lights.

Things You’ll Need

- LED strips

- Connectors

- scissors (or other utility cutting tools)

- tape (optional).

Make A LED Strip 90 Degree Corner In 7 Easy Steps

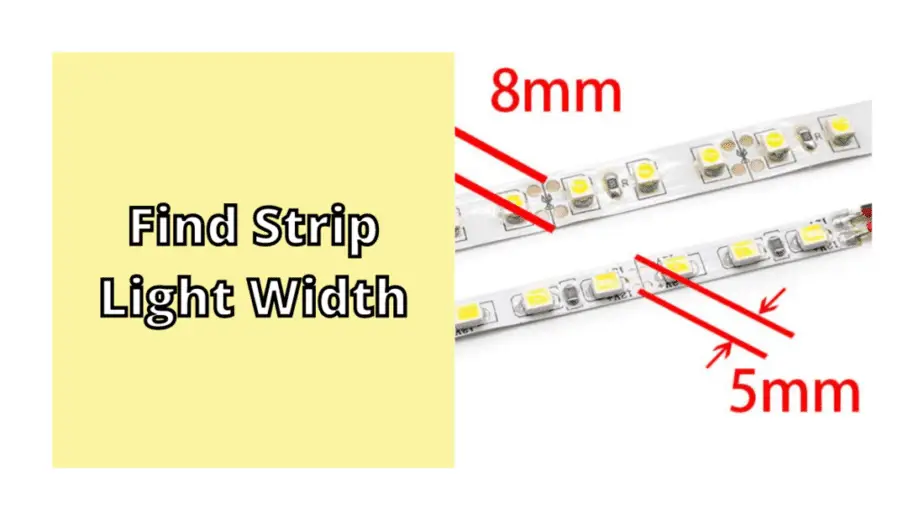

Step 1: Find Strip Light Width

Before you spend money on a connector, at first you need to find out the width of your LED strip light. If the width of your LED strip light is not compatible with the width of your connector, it just won’t work.

The standard width of a light strip is usually 10mm. Most LED light strips are of this width, however there are some exceptions.

Check the packaging that your LED strips came in to find out the width or look online. Then verify whether the connector you want to buy is compatible with that width.

Step 2: Point Out Where You Want To Bend

Before cutting, determine the length where you want to make your cut. Once you have cut the strip in one place, you won’t be able to go back so be very careful during this step.

If necessary, place the strip where you want to put them and draw out the exact area where the strip needs to be cut

Step 3: Cut Strip Light In Point

Now that you’ve marked the area where you want to make the cut, its time to identify the cut line. Most LED strips will have an easily identifiable cut line, marked by a dotted or straight black line with a scissor mark.

Using a sharp pair of scissors, carefully cut along the cut line. If the scissors aren’t sharp, you may damage the strip while cutting.

The opposite side of the cut line will contain the copper pads which connect the circuits in the strips. These copper pads will act as the point of connection for the connectors, so make sure both the cut ends have enough copper padding areas.

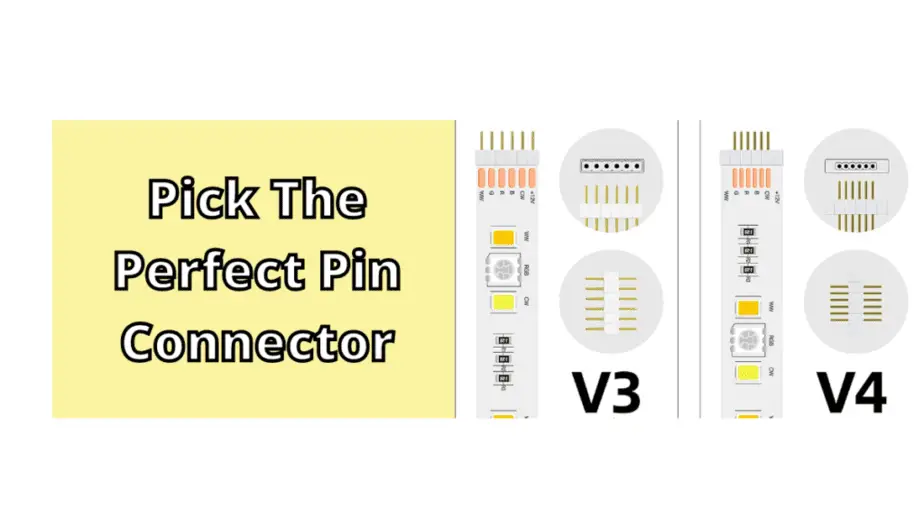

Step 4: Choose The Right Pin Connector

Another thing you need to check before purchasing the connectors for your LED strip 90 degree corner is the pin pattern.

LED strip pin connectors come in various patterns with different number of pins. The most commonly found connectors have 2, 4 or 5 pins.

One easy way to find out the correct pin pattern for your LED strip lights is to look at the pattern of the copper pads that we mentioned before.

If the back of your LED strip has 4 copper pads arranged vertically, that means you’ll need to use a connector with a 4 pin pattern. The same goes for 2, 3 and 5 copper pads.

Step 5: Check The Pin Connector Width

When looking up suitable connectors online, make sure to check the width of the connector you’re about to buy. The connector width should be large enough to accommodate the width of your LED strip.

The product information area on the seller’s webpage should have this information.

Step 6: Join Strip Light With Connector (Back To Back)

Now that you have everything arranged and ready, insert the cut LED strip ends into the connectors. Most connectors will have a clip design, so you should hear a clicking sound if the strip has been inserted properly.

Some connectors come with covers for added safety and protection, you can consider purchasing those as well in order to protect exposed circuitry.

Step 7: Check The Strip Light

Now that the whole setup is connected, before you install the entire thing you should plug in the strip light to power and see if the entire strip gets illuminated.

In case the strip does not work, make sure all the connections have been made properly. Check the connectors for any loose connections. Make sure the cuts you’ve made on the strips are clean.

One issue could be that you connected the strips using the wrong polarity. Make sure the + and – signs of the strips are matching with each other and try again.

Frequently Asked Question

u003cstrongu003eCan You Bend Led Strip 90 Degreesu003c/strongu003e

Even though you can physically bend your LED lights at a 90 degree angle, we strongly recommend against it. Bending or twisting your LED strips increases chance of damaging the delicate components of an LED strip. u003cbru003eLED strip 90 degree corners that have been bent may work in the beginning, but over time your strip will likely not last as long as you’d expect. u003cbru003eMoreover, bending these strips may void manufacturer warranty which will prevent you from replacing these strips.u003cbru003e

u003cstrongu003eHow To Bend LED Strip Light With Wired Jumper Cord Connectoru003c/strongu003e

As mentioned earlier, wired jumper cord connectors are a good option to be considered for making LED strip 90 degree corners. u003cbru003eThe added wire allows you some wiggling room. This can be important, as if you want to change the positioning of your LED strips in the future, this would be a good option.u003cbru003e

u003cstrongu003eCan LED Strip Lights Go Around Corners in Your Roomu003c/strongu003e

If you’re thinking about putting up your LED strip lights around corners, 90 degree back to back connectors and gapless connectors probably would NOT be the best option for you. These connectors are not exactly designed for going around corners.u003cbru003eOne of the best options for this purpose is to use the jumper cord connectors. The loose wire between the connection points allows you to put the connector around corners without putting too much stress on the connector’s electrical components.u003cbru003e

u003cstrongu003eHow Do You Attach LED Strips to A Corneru003c/strongu003e

As said earlier, the jumper cords would be the best option for going around corners. However, if you don’t want to spend more money on connectors or don’t want to cut your strips, just leave a bit of the strip loose around the corner. u003cbru003eThis will make sure that there isn’t too much stress on the strip.u003cbru003e

u003cstrongu003eIs It Okay to Cut LED Strip Lightsu003c/strongu003e

As long as you follow the right procedure, you shouldn’t have a problem cutting LED strip lights. With the right tools, you can do this with minimum risk.u003cbru003eUse a sharp pair of scissors. Carefully cut through the marked cut line. Make sure you leave the copper pads exposed on both cut sides.u003cbru003e

Conclusion

We’ve told you everything there is to know regarding making LED strip 90 degree corners, so if you think your room would look better with 90 degree LED strip lights, its time to go for it.

As long as you do the correct research and follow our instructions correctly, you shouldn’t have a problem performing this. Be very careful as even a small mistake can damage your lighting equipment.

My strong expertise is illuminating spaces. With a keen eye for detail and a passion for transforming environments through lighting, my dream is to leave indelible mark on the world of light design. Below are few facts of my biography, highlighting career and hobbies. Click here to contact me.